Structure and Operating Principle (Figure 14-1 and 14-2)

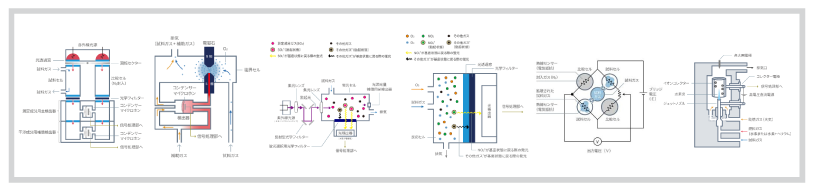

Unlike conventional modulation using a chopper, this method uses a solenoid valve unit to switch at regular intervals to alternately introduce sample gas and reference gas into the same gas cell, so the solenoid valve unit performs the modulation mechanism. An example of an analyzer structure for this method is shown in Figure 14-1.

While modulation by the chopper changes the amount of infrared light source supplied to the sample and reference cells, the cross-modulation method changes the gas flowing to the sample and reference cells. Except for the modulation mechanism, the detection function of measured component and the compensation function for interfering component, which are necessary to detect the concentration of measured component, are the same as those of the infrared gas analyzer described so far, so this section focuses on the operation of the modulation mechanism (Figure 14-2).

Figure 14-2: Principle of Modulation Operation of Cross-Modulation Method

The solenoid valve unit allows the sample gas to flow into the left gas cell and the reference gas to flow into the right gas cell simultaneously. If there is measured gas component in the sample gas, the diaphragm of the condenser microphone will expand to the left side (toward the sample cell) (Figure 14-2, left figure).

Next, the solenoid valve unit is switched and the sample gas flows into the right gas cell and the reference gas flows into the left gas cell simultaneously.

If there is measured gas component in the sample gas, the diaphragm of the condenser microphone will expand to the right side (toward the sample cell) (Figure 14-2, right figure).

This operation is repeated at a regular cycle to modulate the detection signal of the condenser microphone. By swinging the diaphragm of the condenser microphone in the detector to the left and right sides, this method obtains twice the amount of detected signal than using a chopper, thereby improving noise immunity. In addition, a mechanism of flowing a sample and reference gas through each gas cell for measurement makes a result of stable measurement over time by reducing the influence of degradation of infrared light sources and contamination of gas cells for detection signals.