Nitrous Oxide Monitoring for Greenhouse Gas Reduction

HORIBA’s highly accurate Nitrous Oxide (N2O) analyzers represented in various types from stationary to portable, contribute to the environment protection and GHG emissions mitigation by quantification of N2O emission from wastewater treatment plant

Wastewater treatment plants (WWTPs) are significant contributors to greenhouse gas (GHG) emissions, including nitrous oxide (N2O), methane (CH4), and carbon dioxide (CO2). According to the Global Anthropogenic Non-CO2 Greenhouse Gas Emission report, emissions from WWTPs are projected to increase by about 22 % from 2005 to 2030, rising from 82 to 100 million metric tons of CO2 equivalent (MtCO2e)*1. This increase in N2O emissions is driven by the population and income growth, which leads to higher protein consumption per capita and subsequently greater nitrogen loads into sewage. Consequently, this situation significantly contributes to the rise in N2O emission from WWTPs*1.

Given that global warming potential of N2O is 298 times that of CO2, accurately quantifying N2O emission from WWTPs and improving their operations are crucial steps towards mitigation of N2O emissions on the path to achieving a net-zero society.

The international methodology for quantifying emissions, established by IPCC*2 Guidelines, includes Tier 1, Tier 2, and Tier 3 methods. Under Tier 3, countries with advanced methodologies and reliable data can use country specific method*2. As a result, many universities in developed countries are currently engaged in research, measurement campaigns, and formulation of national measurement guidelines.

One significant challenge faced by operators is accurate measurement of N2O emissions, as there can be potential interference from other gas in the sample gas. This interference can lead to inaccuracies in N2O measurements and ultimately result in the incorrect calculation of N2O emission factors.

Accurate measurement is therefore a primary challenge in correctly assessing N2O emissions from WWTP facility for consideration of improvements in treatment processes and new development of advanced treatment technologies with enhanced nitrogen removal capabilities.

*1 Global Anthropogenic Non-CO2 Greenhouse Gas Emissions: 1990-2030 (Revised Dec.2012)

Office of Atmospheric Programs Climate Change Division U.S. Environmental Protection Agency

*2 The 2019 Refinements to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories

Chapter 6 Wastewater Treatment and Discharge

The analyzer can be equipped with interference compensation function (option)

Available with simultaneous measurement of up to 4 components by one unit (Example: N2O, CH4, CO2 and O2*3)

*3 In design with 4 components, oxygen measurement technology is fixed to Galvanic.

Multipoint switching system with periodic measurement of each sampling point

Figure 1: Multi-Component Gas Analyzer VA-5000 and Sampling Unit VS-5000

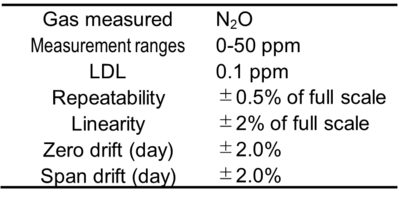

Table1:Specification

Multi-Component Gas Analyzer

Portable Gas Analyzer

Stack Gas Analysis System

Do you have any questions or requests? Use this form to contact our specialists.