Surface Area Analysis

The surface area of a material is, in many cases, as important as the chemical properties of that material and can impact many aspects of a material’s performance. This is because the interface of the material influences how solids behave in the presence of other materials, be they gases, liquids, or other solids.

This affects things such as:

- Shelf life, stability, dissolution and efficacy of pharmaceutical powders and tablets.

- The rheological properties and hiding powers of pigments, paints, and coatings.

- The ability for materials like catalysts, adsorbents, filtration materials and air separation products to react in the designed application.

- Refine oil products.

- Purify air, separate gases, or remove harmful by-products.

- The creation and performance of ceramics used in applications ranging from dinner plates, dental implants, to electronics.

- In batteries, powder surface area influences electrode performance and the fabrication process as well as the electrolyte interaction and electrochemical stability of many types of batteries.

Measuring specific surface area (surface area per unit of mass) of these materials through gas adsorption is a common technique used in materials science, chemistry, and many industrial settings. To learn more about surface area analysis and physisorption technology, visit our Surface Area Technology page.

HORIBA's SA-9650 series analyzers offer the perfect solution to a myriad of surface area analysis needs

Automatic Analysis

Starting an analysis is simple and requires as little as a single push of a button. The entire analysis is completed without further interaction and avoids the manual steps required with many similar analyzers. Once the analysis is initiated, calibration occurs, and the liquid nitrogen Dewars are automatically raised and lowered under computer control. Upon analysis completion, data is automatically produced and made available.

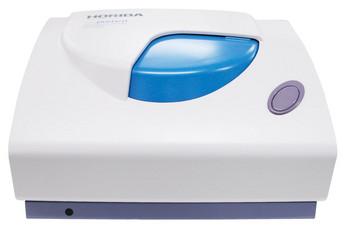

Compact, All-in-One

The SA-9650's redesigned cabinet allows front facing access to all operational touch points with no side access required. No separate analysis and preparation devices are needed as with many alternative analyzers. Control using the built-in computer and keyboard to maximize space savings in your lab.

Safe and Secure

Both the Prep and Test Stations are protected by transparent safety doors and must be properly closed prior to operation. Heat will automatically shut off at the Prep station and the Test station Dewar tray will not move if their station doors are opened, keeping operators safe.

No User Calibration Required

To ensure repeatable accuracy, the SA-9650 performs an automatic calibration before every measurement. And from there, the SA-9650 technology eliminates variables otherwise introduced by operator involvement.

No Freespace or Void Analysis Required

Due to the design of the flowing gas or dynamic method, no additional time is spent measuring the sample tube volume or freespace. Furthermore, no requirements for measuring sample tube volumes or calibration are required.

Lowest Cost of Ownership

The use of mass flow controllers in multipoint versions of the SA-9650 series automatically create the necessary mixtures of nitrogen and helium for multi-point BET surface area analysis. This lowers the total cost of ownership by eliminating the need to purchase expensive gas mixtures or external gas mixer systems. Straightforward design ensures service costs are minimal compared to more complex, static volumetric technology.

Detector Protection

An automated measurement station bypass loop, controlled by a cell detector switch, provides an uninterrupted gas mixture flow through the Thermal Conductivity Detector in case of missing or broken sample cell.

Electronic Valves

Reliable electronic valves eliminate the need for a compressed air or gas supply to actuate valves during the measurement process, further lowering cost of ownership.

Improved Gas Handling

Thoughtful design of manifold layout and valve selection result in more stable, balanced flow, improving repeatability, lowering maintenance costs, and easing operation.

Robust Dewar Elevator System

A rugged mechanical design means smoother and reliable movement of the Dewar tray that raises and lowers the LN2 Dewars.

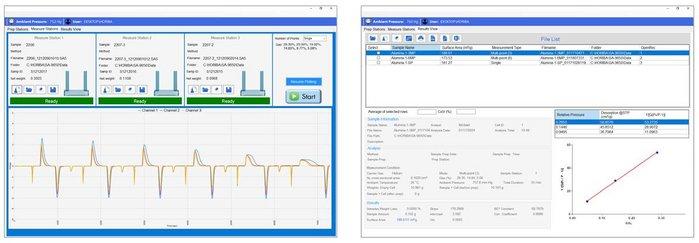

Newly Designed Software

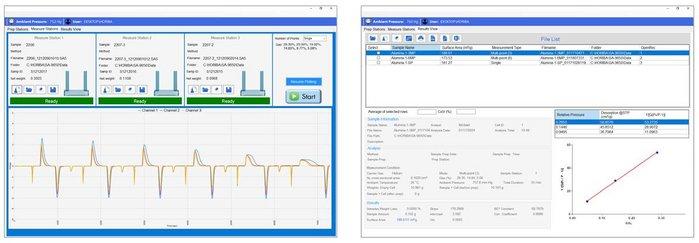

Users can easily operate the analyzer by following a simple, 3-step process:

- Type in the sample name

- Choose the measurement type

- Click “Start” to begin measurement

View in real-time to see the auto-calibration, adsorption, and desorption. A full surface area report will be complete in minutes.

Flexibility

Built-in functions allow for the optimization of the system for different sample types.

- Gas concentration of mixed gases may be precisely controlled to give results identical to the multipoint method.

- A wide variety of sample cells are available, allowing measurements to be made on diverse sample types.

Use the enhanced SA-9650 software to control the instrument via USB connection to a Windows PC or users can easily operate the analyzer by using the built-in computer with LCD display and keyboard.

High Throughput

Every SA-9650 model includes three sample preparation stations to improve workflow. Depending on the sample, users can complete a measurement procedure in 15 minutes for single-point or 45 minutes for multi-point.*

*Sample preparation (i.e. degassing) must be performed prior to measurement. Typical degas time is 1 hour at 200°C.

Webinar

Fast and Reliable Surface Area Gas Analysis with the NEW SA-9650 Analyzer