HORIBA, a leading supplier for emission measurement and automotive testing systems, extends its measurement capabilities of solid particle numbers further into the nanoscale range. The introduction of the new MEXA-2010 Solid Particle Counting System (SPCS) enables particle measurements below the current legislative detection limit of 23nm. Following recent scientific evidence on the harmfulness of nanoparticles in this size regime, HORIBA’s improved SPCS anticipates upcoming European legislation aimed at lowering the size limit of particles to be characterized in automotive exhaust and brake emissions. HORIBA thus provides the automotive industry with the necessary measurement technology to prepare for future legislation.

The basis for this technology is the well-established SPCS, the market leading instrument for particle number homologation. Using the latest Catalytic Stripper technology, the challenge of removing the large number of non-solid particles in the Sub-23nm range from the sample is overcome. “Ensuring that the relevant solid particles reach the detector gets even more difficult as particle sizes decrease,” explains Dr. Florian Hüwe, Product Manager for Automotive Particulate Emissions at HORIBA Europe. “Accurate pre-dilution and transfer of the sample from the exhaust duct to the detector is provided by the superior penetration performance of our SPCS. Besides introducing new instruments to the market, these new technologies allow us to offer upgrades to the existing MEXA-2000SPCS during annual maintenance cycles. Within the EU-funded PEMs4Nano project, we are also developing an upgrade to our portable emission measurement systems OBS-ONE-PN according to the new size limit.” The combination of the SPCS with the micro dilution tunnel MDLT-ONE allows for a characterization of particulate emissions according to both the mass (PM) and number (PN) standard. These possibilities underscore HORIBA’s aim to provide environmentally friendly, long-term product support securing customer investments and anticipate future legislative changes.

Overcoming calibration challenges

The new detection limit also poses unique challenges regarding system calibration. HORIBA developed an “Automated Validation and Calibration System” (SPCS-AVACS). This novel system provides customers with a state-of-the-art system to verify their particle number measuring instrument directly on-site. A prototype of the SPCS-AVACS was presented on this year’s Testing Expo exhibition in Stuttgart, Germany. Based on the positive reception by customers, HORIBA is now finalizing its development and plans to introduce it to the market in 2020.

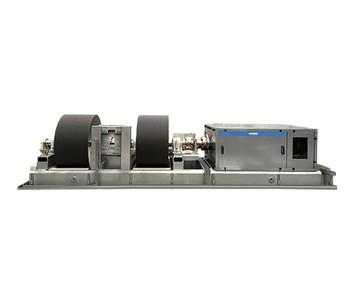

The wide spectrum of available measurement instruments is an expression of HORIBA’s philosophy to be a partner of the automotive industry in all matters regarding particulate emissions. HORIBA provides complete, future oriented testing solutions that support customers in their efforts to stay ahead of future legislations. For example, HORIBA’s Brake Dust solution presented in spring 2019 combines the in-depth knowledge of particle emission and brake testing by incorporating emission measurement technology into an automated brake dynamometer test stand.